|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UV 경화 시스템, 모듈형 UV 경화시스템 UV 세정 시스템 UV 노광 시스템 SPOT UV, UV LED FLOOD UV 외 |

MIR / NIR 건조시스템 적외선 건조시스템 IR / 열풍 건조시스템 소성로 (FIRING FURNACE) |

펄스UV 경화 시스템 펄스UV 세정 시스템 외 |

제논 조사장치 75W, 100W, 150W 200W, 300W, 1 kW 3 kW ~ Max. 15 kW

|

내후성 시험장비 WEATHER TESTER 기타 주문형 시험장비 |

광량계, 광계측기 광분석시스템 광모니터링 시스템 외 |

솔라셀 제조장비 SOLAR FIRING SOLAR SIMULATOR (CELL, MODULE) SOLAR CELL PRINTING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X-UV 경화 시스템 PHOTONIC ACTIVATION X-UV 살균, 세정 외 |

MIR / NIR 램프, 제논램프 펄스UV램프 솔라시뮬레이션 램프 외

|

X-LIGHT 어닐링 시스템 PHOTONIC CURING SYS |

(자동, 반자동, 인라인) |

|

LED BLU 휘도 검사시스템 LED 조도 검사시스템 SWIR검사, X-RAY검사 NEUTRON 검사시스템 |

솔라셀 제조 라인 인쇄 코팅, 전처리, 건조, 경화 생산 라인 롤 코터 / DIP 코터 라인

|

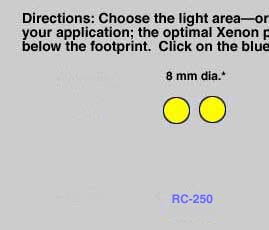

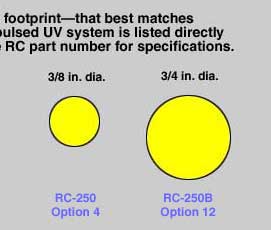

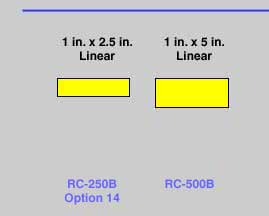

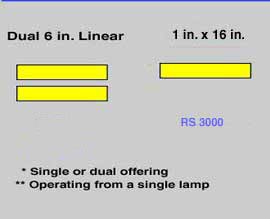

the target “footprint”.

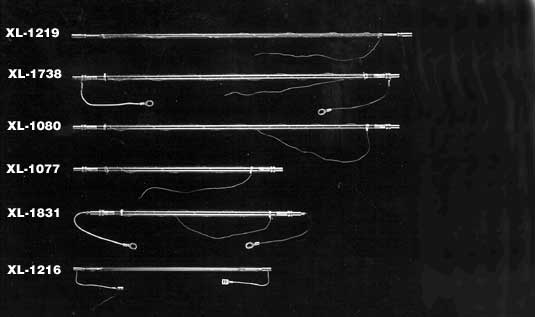

Traditionally, mercury UV lamps have been limited to short arc or linear lamp

designs. There are no such limits on pulsed UV lamps. The ability to shape the

lamp to the application, providing better uniformity and enhanced matching of

the UV light with the substrate, is a benefit for demanding applications.

the target “footprint”.

Traditionally, mercury UV lamps have been limited to short arc or linear lamp

designs. There are no such limits on pulsed UV lamps. The ability to shape the

lamp to the application, providing better uniformity and enhanced matching of

the UV light with the substrate, is a benefit for demanding applications.